The Basic Principles Of Turbochargers

Table of Contents7 Simple Techniques For TurbochargersGetting The Turbochargers To WorkSome Of Turbochargers

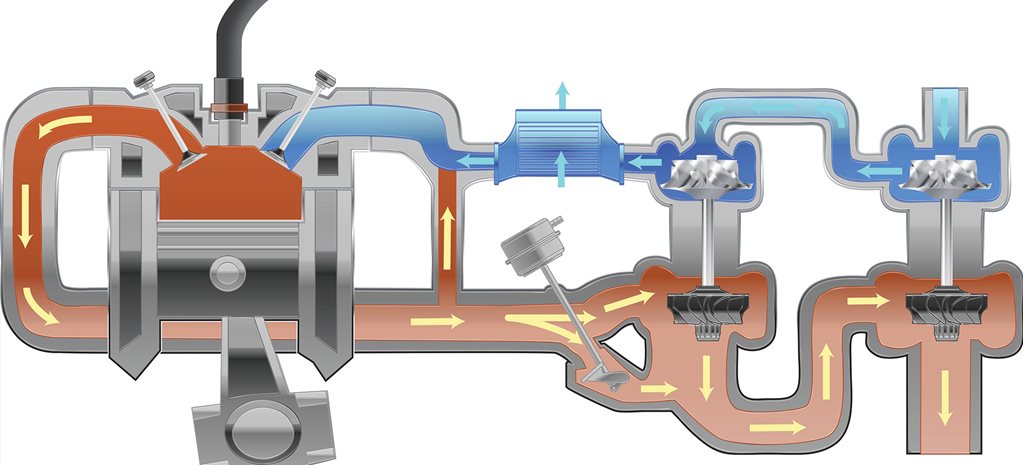

For instance, in Opel bi-turbo Diesel, only the smaller turbocharger works at low speed, offering high torque at 1,5001,700 rpm - turbochargers. Both turbochargers operate together in mid range, with the smaller one pre-compressing the air, which the bigger one further compresses. A bypass valve controls the exhaust circulation to each turbocharger.

Smaller turbochargers have less turbo lag than bigger ones, so typically two small turbochargers are utilized instead of one large one. This setup is popular in engines over 2. 5-litres and in V-shape or fighter engines. Twin-scroll or divided turbochargers have 2 exhaust gas inlets and two nozzles, a smaller sized sharper angled one for fast action and a bigger less angled one for peak performance.

In twin-scroll designs, the exhaust manifold physically separates the channels for cylinders that can hinder each other, so that the pulsating exhaust gasses circulation through different spirals (scrolls). With typical firing order 1342, two scrolls of unequal length set cylinders 1 and 4, and 3 and 2. This lets the engine effectively utilize exhaust scavenging strategies, which reduces exhaust gas temperatures and emissions, enhances turbine effectiveness, and minimizes turbo lag obvious at low engine speeds.

The vanes are positioned simply in front of the turbine like a set of somewhat overlapping walls. Their angle is adjusted by an actuator to block or increase air circulation to the turbine. This variability maintains an equivalent exhaust velocity and back pressure throughout the engine's rev range. The outcome is that the turbocharger improves fuel effectiveness without a visible level of turbocharger lag.

The compressor is made up of an impeller, a diffuser and a volute housing. The operating series of a compressor is described by the "compressor map". The circulation series of a turbocharger compressor can be increased by permitting air to bleed from a ring of holes or a circular groove around the compressor at a point slightly downstream of the compressor inlet (but far nearer to the inlet than to the outlet).

The Turbochargers PDFs

It accomplishes this by requiring a simulation of impeller stall to happen continually. Permitting some air to leave at this place prevents the onset of rise and widens the operating variety. While peak efficiencies might decrease, high effectiveness may be attained over a greater series of engine speeds. Boosts in compressor efficiency lead to slightly cooler (more dense) intake air, which enhances power.

The ability of the compressor to offer high increase at low rpm may likewise be increased partially (because near choke conditions the compressor draws air inward through the bleed course). Ported shrouds are used by many turbocharger manufacturers. The centre hub rotating assembly (CHRA) houses the shaft that links the compressor impeller and turbine.

Ball bearings designed to support high speeds and temperature levels are in some cases used instead of fluid bearings to support the turbine shaft. This assists the turbocharger speed up quicker and lowers turbo lag. Some variable nozzle turbochargers utilize a rotary electric actuator, which utilizes a direct stepper motor to open and close the vanes, rather than pneumatic controllers that run based on air pressure.

When the pressure of the engine's consumption air is increased, its temperature level also increases. This occurrence can be discussed through Gay-Lussac's law, specifying that the pressure of a given quantity of gas held at constant volume is straight proportional to the Kelvin temperature. With more pressure being contributed to the engine through the turbocharger, overall temperatures of the engine will also rise.

The warmer the intake air, the less dense, and the less oxygen offered for the combustion event, which minimizes volumetric performance. Not just does extreme intake-air temperature lower performance, it also causes engine knock, or detonation, which is devastating to engines. To make up for the increase in temperature level, turbocharger units often utilize an intercooler in between succeeding stages of boost to cool off the consumption air.

Little Known Questions About Turbochargers.

There are 2 locations on which intercoolers are commonly mounted. turbochargers. It can be either mounted on top, parallel to the engine, or find here installed near the lower front of the vehicle. Top-mount intercoolers setups will result in a decline in turbo lag, due in part by the area of the intercooler being much closer to the turbocharger outlet and throttle body.

Front-mount intercoolers can have the prospective to provide better cooling compared to that of a top-mount. The location in which a top-mounted intercooler is located, is near among the hottest areas of a cars and truck, right above the engine. This is why most makers include big hood check my reference scoops to help feed air to the intercooler while the vehicle is moving, however while idle, the hood scoop offers little to no advantage.

With more range to take a trip, the air distributed through a front-mount intercooler might have more time to cool. Methanol/water injection has been around because the 1920s however was not used until World War II. Adding the mixture to intake of the turbocharged engines reduced operating temperatures and increased horse power.